AXIS Valves & Gauge Valves

AXIS Valves & Gauge Valves

VALVES

Valves PDP, or Pressure Drop Performance, refers to the measurement of the pressure difference that occurs as a fluid or gas moves through a valve. This measurement is important in determining the efficiency and effectiveness of a valve. A valve with a higher PDP means that more pressure is being lost as the fluid or gas moves through the valve. This can result in inefficiencies and added costs for energy consumption. On the other hand, a valve with a lower PDP means that less pressure is being lost and therefore the valve is more efficient. In order to optimize valve performance and minimize energy costs, it is important to choose a valve with a PDP that is appropriate for the specific process and requirements at hand.

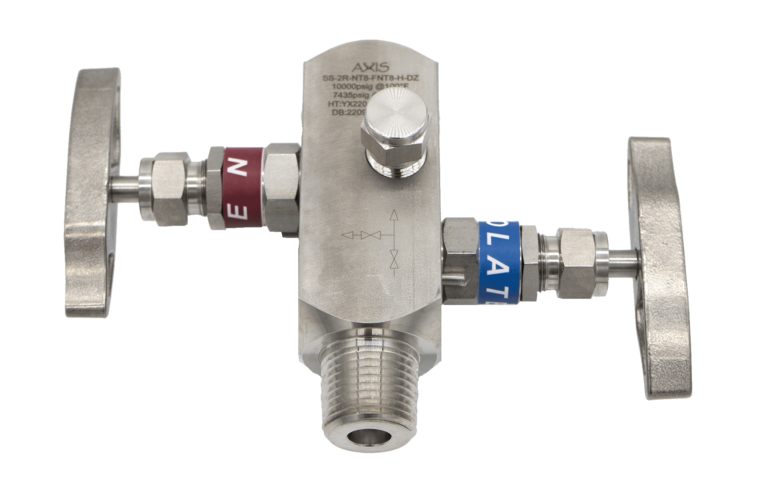

Block & Bleed Valves

The Axis block and bleed valve is designed for mounting to pressure gauges, pressure transmitters, or pressure switches. The valve features a traditional two-valve block and bleed design with a standard vent/calibration connection of ¼” FNPT. Additional features include a near-to-shape forged body, one-piece stem, non-rotating ball tip, and stem seals engineered to provide a bubble-tight seal.

Ball Valves

Our 1/2″ ball valves have a reduced handle so they can be easily threaded into telemetering taps, Male x Female and Female x Female Designs, Investment casting body and blow-out proof stem, Lockable handle and reliable sealing, easy operation, low maintenance, and cost-effective

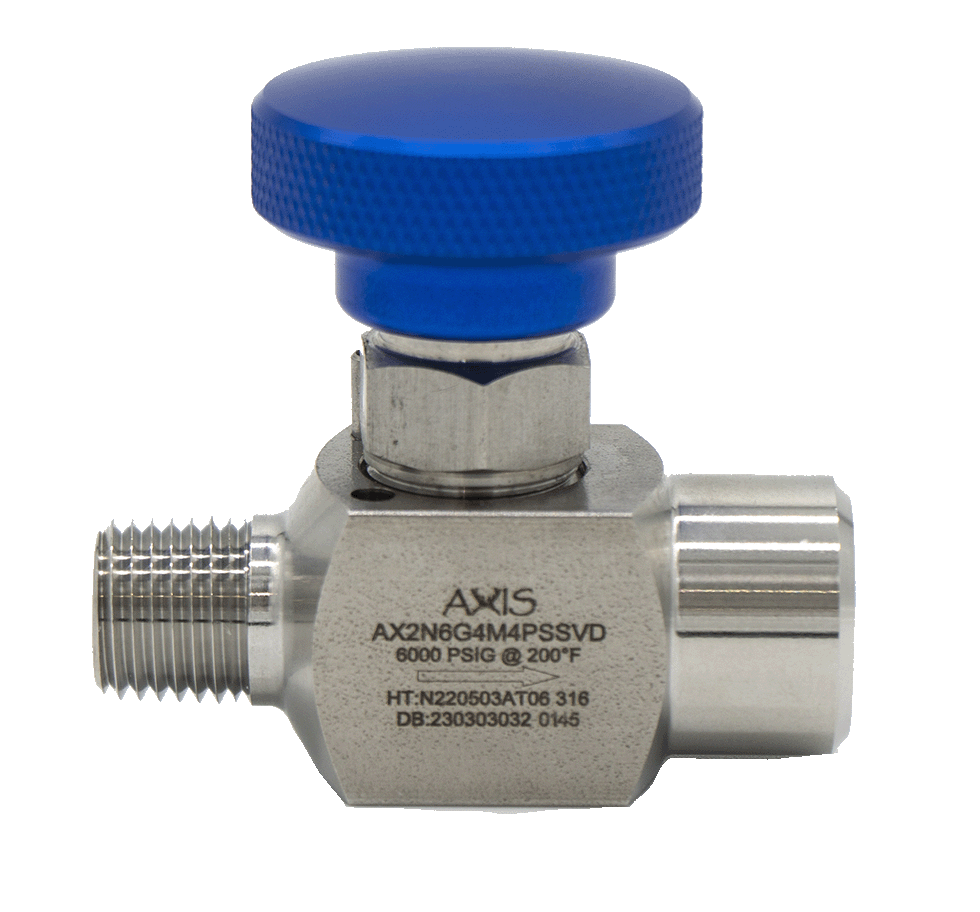

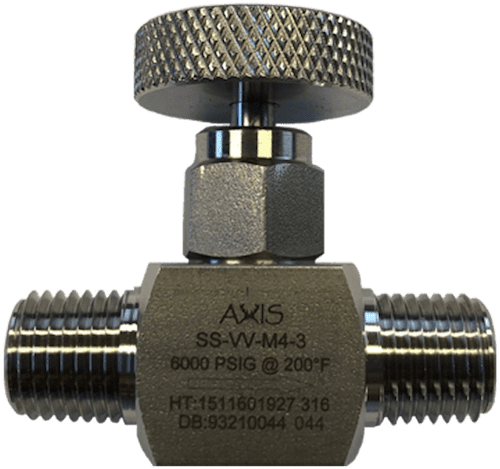

Needle Valves

Mini Needle Valve features

Standard hard seat design

Viton O-Rings standard in all valves

Packing below stem thread isolates thread lubricants from media

Machined seat allows metal to metal seal

Material Test Reports available on all valves

Mini Gas Valve features

Unique soft seat design allows pressure up to 6000 PSI

Double O-Ring packing below stem threads prevents corrosion

Stem threads formed by rolling provide improved strength and smooth operation

Optional Quick Calibration connections

Bodies and bonnets are lot code stamped to provide full material traceability

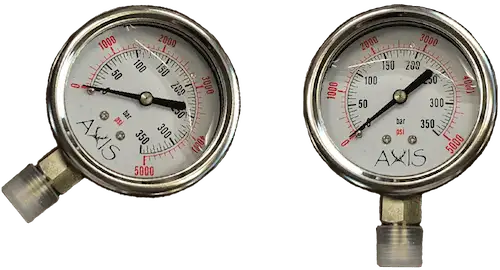

Gauge Valves & Gauges

Pressure ranges from 30 PSI to 5,000 psi

Lower mount and center back mount styles are available

Internal fluid enhances durability compared to other style gauges

Pressure measurement in both PSI and BAR

Liquid inside the gauge helps absorb vibrations, keeping the needle steady for more accurate readings